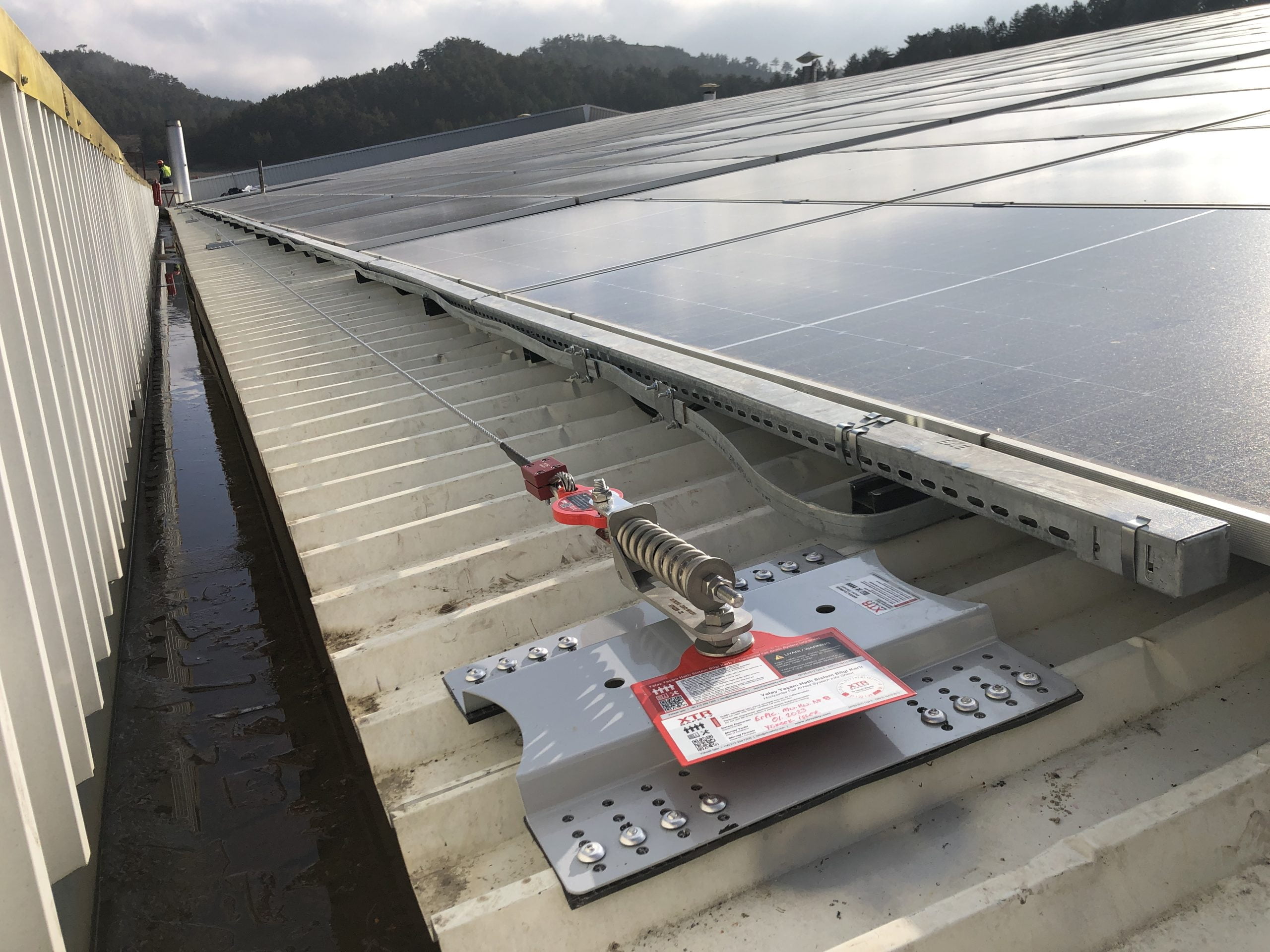

Horizontal lifeline is a practical and economical solution for the safety of the personnel involved in rooftop works (stream cleaning, maintenance and repair, solar panel projects, chimney measurements, etc.).

- On sandwich panel and trapezoidal sheet type roofs, a lifeline can be installed directly on the roof surface.

- XTR Safety, specially designed panel anchors cover a large area on the roof surface, increasing surface strength.

- With strong rivets, the anchor is fixed to the roof surface and a long life is ensured.

- The layout planning of the lifelines to be installed on the roof should be carried out by professionals who are familiar with the principles of working at height.

Application

25 Year Warranty

All XTR Safety products are covered by a 25-year manufacturer’s warranty

Stainless Steel & Aluminum

XTR Safety products are manufactured with stainless steel and aluminum materials with high corrosion resistance

Insurance

All our operations are protected by insurance with a coverage of 1.000.000 USD against installation errors

Panel type roofs can be sandwich panels or trapezoidal sheets. Sandwich panel roofs are roughly formed by filling the space between two trapezoidal sheets with insulation material. For panel type roofs, installation is made directly on the sheet considering the top sheet condition. Conditions such as the thickness of the sheet, the material of the sheet, the age and wear and tear of the roof will determine the installation method.

In sandwich panel and trapezoidal type roofs, if the sheet condition is suitable, anchors with large surface area are fixed directly on the sheet. XTR Safety recommends the use of rivets as fasteners for anchor installation. Smart screws etc. as fasteners. The use of elements may cause problems such as loosening, disassembly and insulation problems in the long term. XTR Safety panel anchors are fixed to roofs with insulated rivets with appropriate resistance.

In roofs where the sheet condition is not suitable, the load-bearing elements under the roof are used for anchoring. In this installation method, the roof is cut to reach the concrete, steel or wooden carriers under the roof and the anchor is fixed to these elements. The anchor fixed to the carrier is removed and left on the roof and re-insulated around it. Careful isolation is extremely important in this method. XTR Safety recommends working with professional insulation companies for this installation method.

In cases where the panel sheet is to be used as a mounting method, the sheet thickness is important. The minimum sheet thickness within the shock damping capability of the lifeline system is determined according to the manufacturer’s instructions. In the installation of XTR Safety panel anchors, a minimum thickness of 0.7 mm for aluminum type roofs and 0.5 mm for steel roofs is required for sandwich panels. For trapezoidal type roofs, a thickness of 1 mm is required if it is aluminum and 0.7 mm if it is steel.

When fixing the anchors to the roof surface, the boundary points of the sheets should be avoided as much as possible. The ridge sheet on the full ridge should not be used as an anchorage fixing surface. Coatings in roof gutters should not be used as an anchoring surface. Railings and chimneys on roofs cannot be used as anchorage points.